Real-World Implementations of MainVerse Technologies

MainVerse isn’t just about innovative technology—it’s about transforming operations in the field. Our pilot projects bring our autonomous unmanned solutions and digital twin platform directly into action across multiple industries. These pilots demonstrate how MainVerse can deliver safer, more efficient, and highly reliable inspections in environments where traditional manual approaches are risky or impractical.

Increased

Efficiency

Enhanced

Safety

Improved Maintenance

Regulatory Compliance

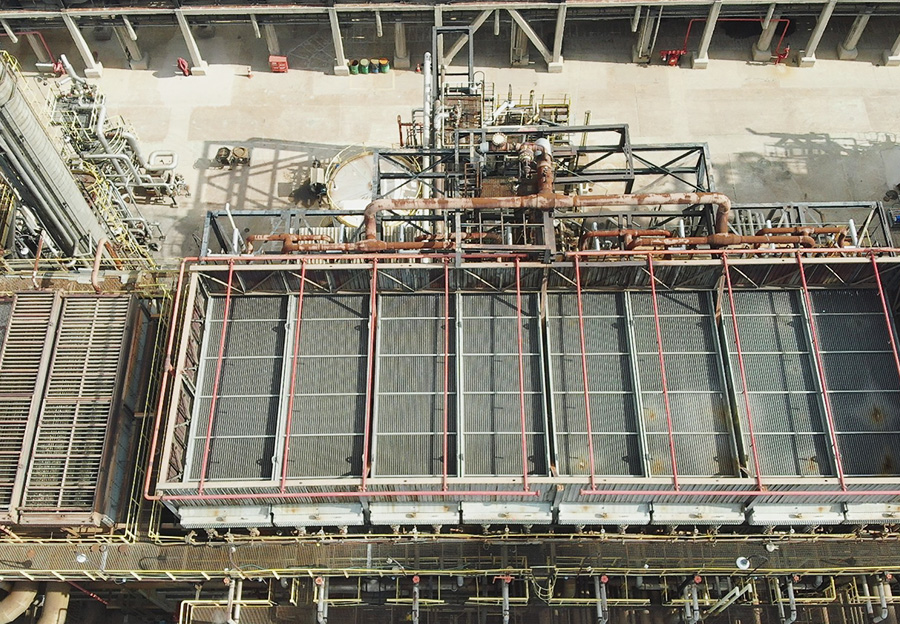

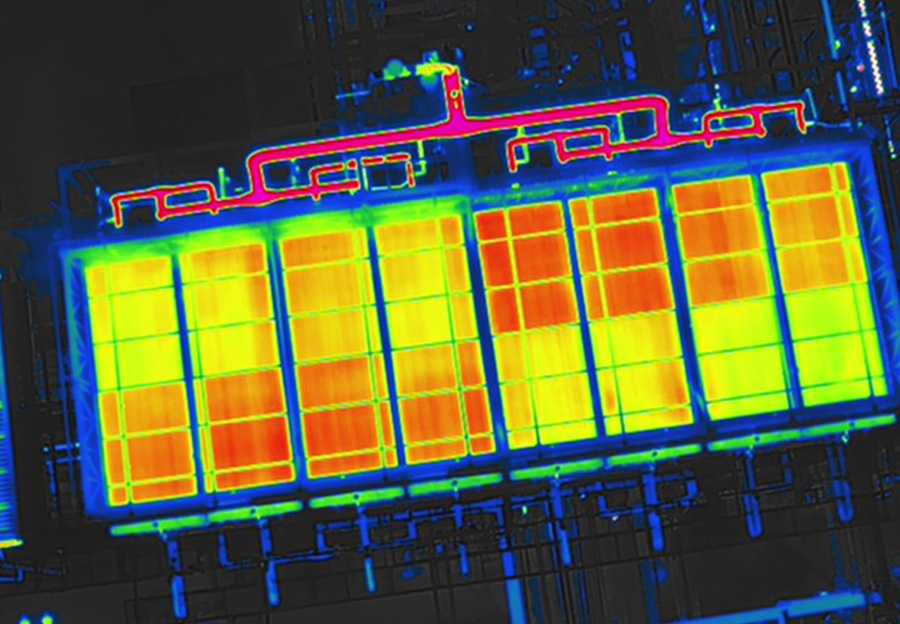

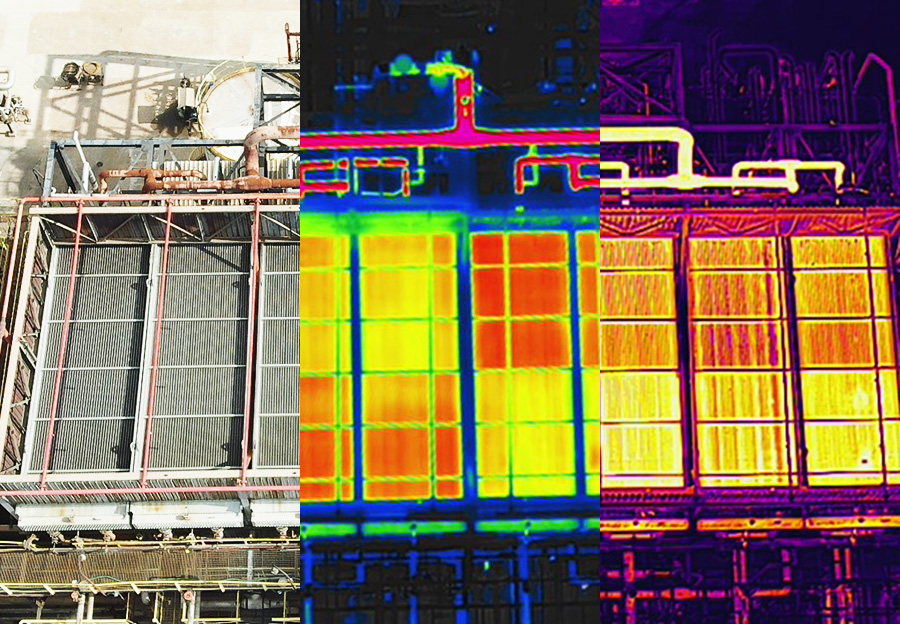

Energy Sector – TÜPRAŞ Pilot

Utilize autonomous drones equipped with advanced gas detection sensors to perform remote inspections in hazardous areas.

- Enhanced Safety: Drones reduce the need for manual inspections in areas with potential gas leaks.

- Regulatory Compliance: Continuous, accurate monitoring of multiple gas types helps meet stringent safety standards.

- Operational Efficiency: Automated data collection and real-time AI analysis facilitate prompt leak detection and proactive maintenance.

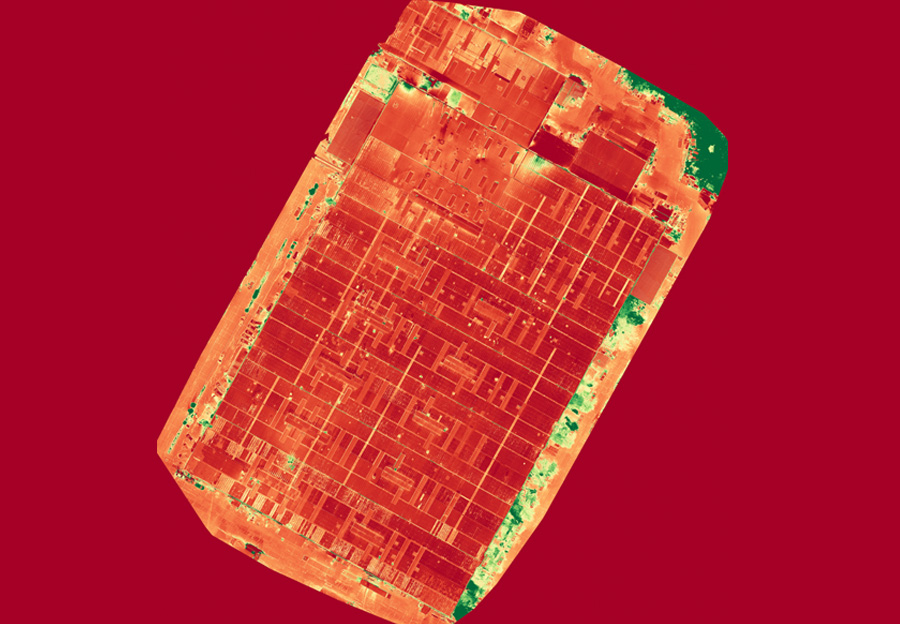

Manufacturing – WAT Pilot

Deploy drones to inspect large factory roofs, detecting structural faults, foreign materials, and other anomalies that could impact operational safety and efficiency.

- Reduced Downtime: Early anomaly detection minimizes costly production interruptions.

- Cost Savings: Automated inspections replace labor-intensive manual checks.

- Precision Maintenance: AI-driven insights help maintenance teams prioritize and schedule interventions accurately.

Food Processing – Kerevitaş Pilot

Implement autonomous guided vehicles (AGVs) with integrated sampling devices to monitor floor and air quality.

- Optimized Sampling: The digital twin platform enables precise selection of sampling locations and intervals.

- Hygiene and Compliance: Automated, regular sampling ensures consistent high standards in hygiene and safety, reducing the risk of contamination.

- Streamlined Operations: Data-driven insights allow maintenance teams to target interventions and improve overall facility management.